Manufacturers face rising pressure to increase throughput, reduce errors, and maintain consistent quality across every production shift. Traditional visual checks are slow, subjective, and limited to small samples. With production lines now generating continuous image and video streams, real-time automation gives plants a way to inspect every unit without slowing the line.

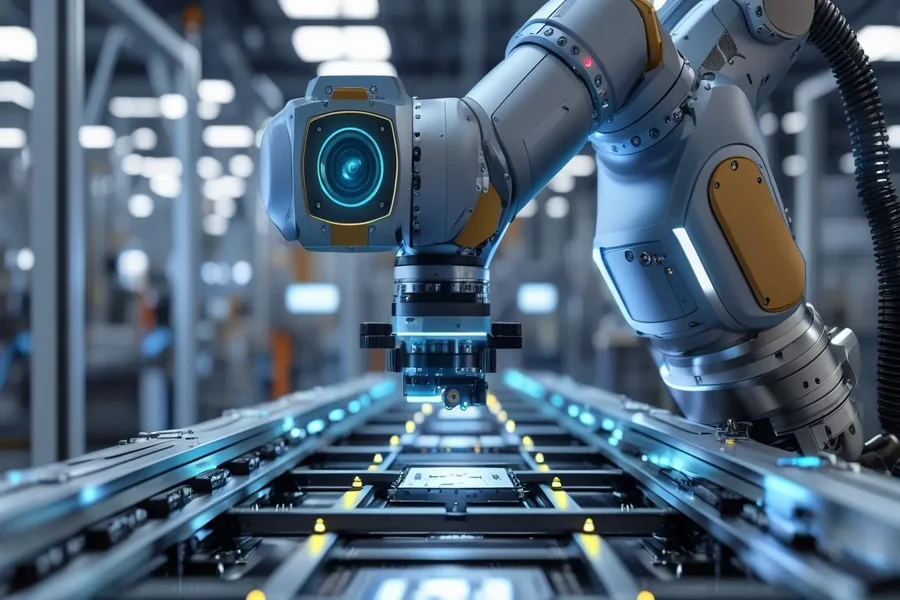

Across factories, teams are adopting enterprise-grade computer vision services to monitor product quality, detect anomalies, and reduce manual workload. These systems use deep learning to analyze thousands of images per second and highlight issues before they reach downstream operations.

Why Manual Inspection Fails at Scale

Human inspectors get tired, lighting changes throughout the day, and production speed keeps increasing. Even in well-run factories:

- Small defects slip through

- Operators can’t check every item

- Errors compound during peak load

- Rework and scrap increase during high-volume runs

Computer vision solves these limitations by maintaining consistent vigilance and providing instant feedback to operators.

How Real-Time Visual Intelligence Works on the Line

Cameras monitor each station or conveyor. Modern models perform:

- Object detection to check components or presence

- Segmentation to identify surface issues

- Anomaly detection to flag deviations in shape or color

- Label and packaging verification for compliance

Signals are sent to dashboards or PLCs within milliseconds. Defects are removed early, reducing downstream failures and warranty risk.

Plants also apply these systems for safety and PPE monitoring. Visual checks ensure workers follow helmet, vest, and glove requirements, with alerts triggered when policies are missed.

Why Manufacturers Are Adopting Computer Vision Faster Than Ever

The technology has moved from experimental to reliable. Edge hardware such as Jetson-based devices enables real-time analysis without cloud latency. Models trained with domain-specific datasets consistently outperform manual checks, especially for fine-grained defects or fast-moving lines.

Most importantly, factories gain the ability to measure their process continuously. By turning visual data into structured insights, quality teams track trends, understand root causes, and plan targeted improvements.

Final Takeaway

Real-time inspection has shifted from a nice-to-have to a core requirement for competitive plants. With production lines running faster and customers expecting flawless output, computer vision offers the accuracy and coverage that human-only checks can’t match, with insights from nebulic.